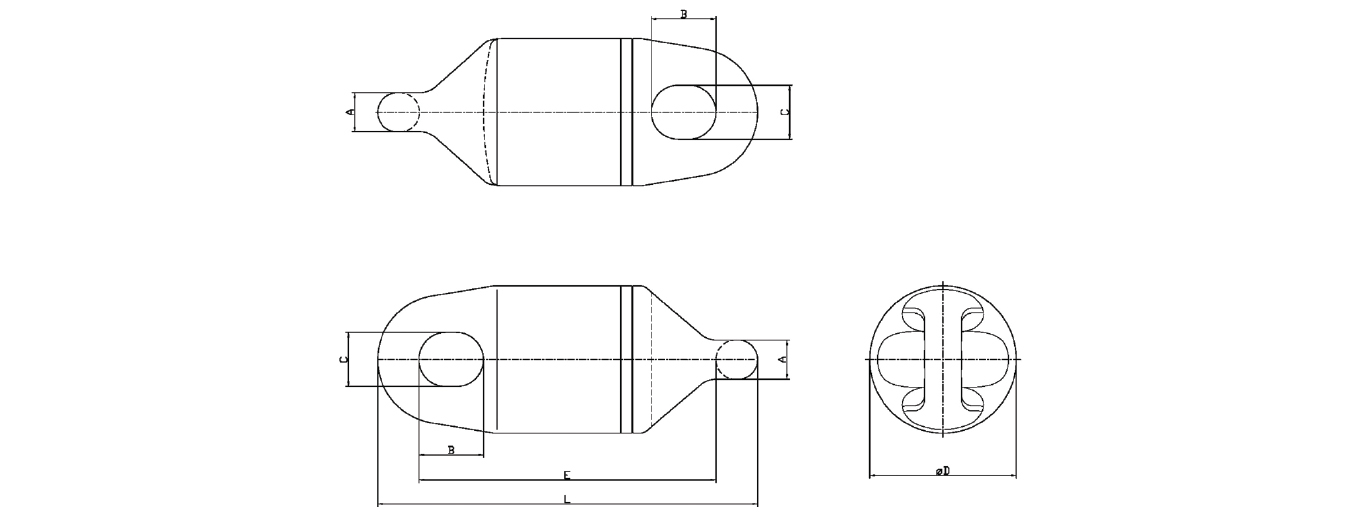

High performance swivel for temporary moorings

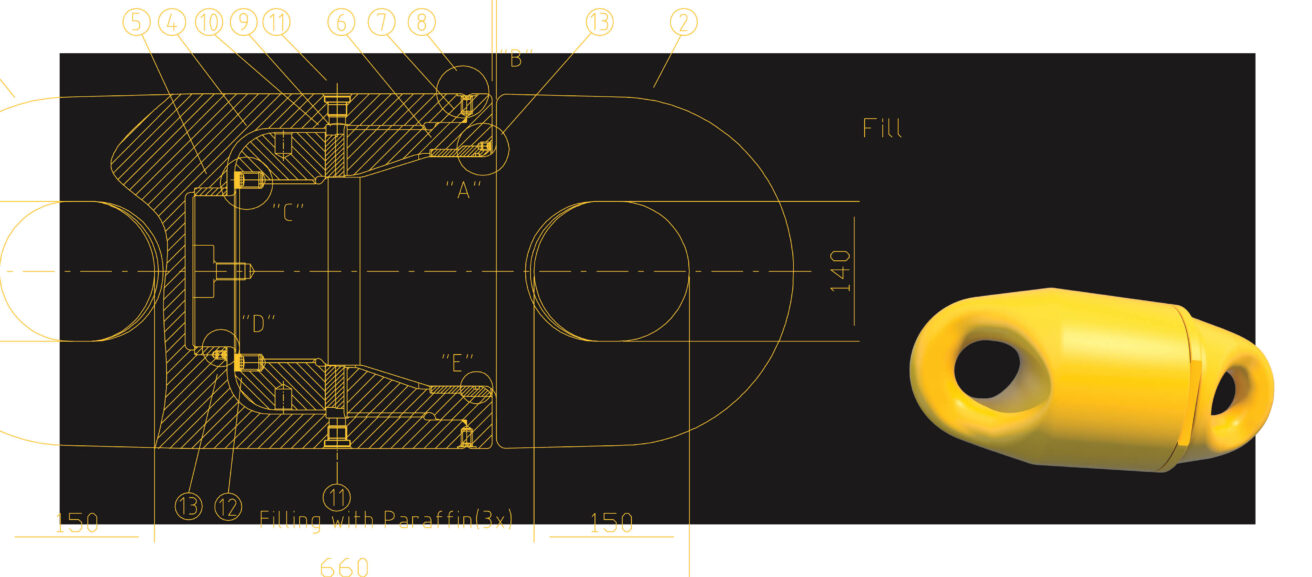

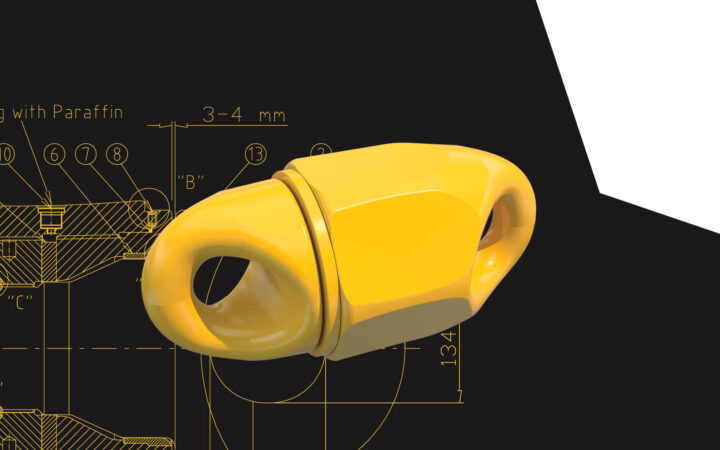

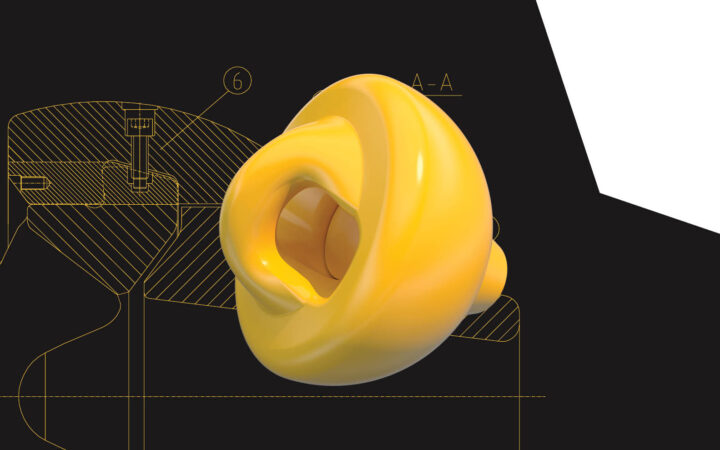

The MoorLink mooring chain swivels are supplied in either forged or cast versions. The structural design is thoroughly analyzed by FEM-analysis and allows the swivel to run through a fairlead, chaser ring or over an anchor handler stern roller under high load, avoiding damage to the bearing system or any other swivel part. The bearing consists of a high grade, maintenance free bronze alloy slide bearing. All MoorLink mooring chain swivels are approved by the major certifying authorities. See drawings and type examples listed below.

| Type | 251 | 177 | 231 | 193 |

| MBL (kN) | 5160 | 6001 | 7210 | 8120 |

| A (mm) | 76 | 80 | 91 | 95 |

| B (mm) | 127 | 130 | 142 | 148 |

| C (mm) | 121 | 133 | 134 | 133 |

| Forged or cast grade 4 steel |

| Certified by ABS, DNV GL or others |

Please note: Other certified types and sizes are available upon request

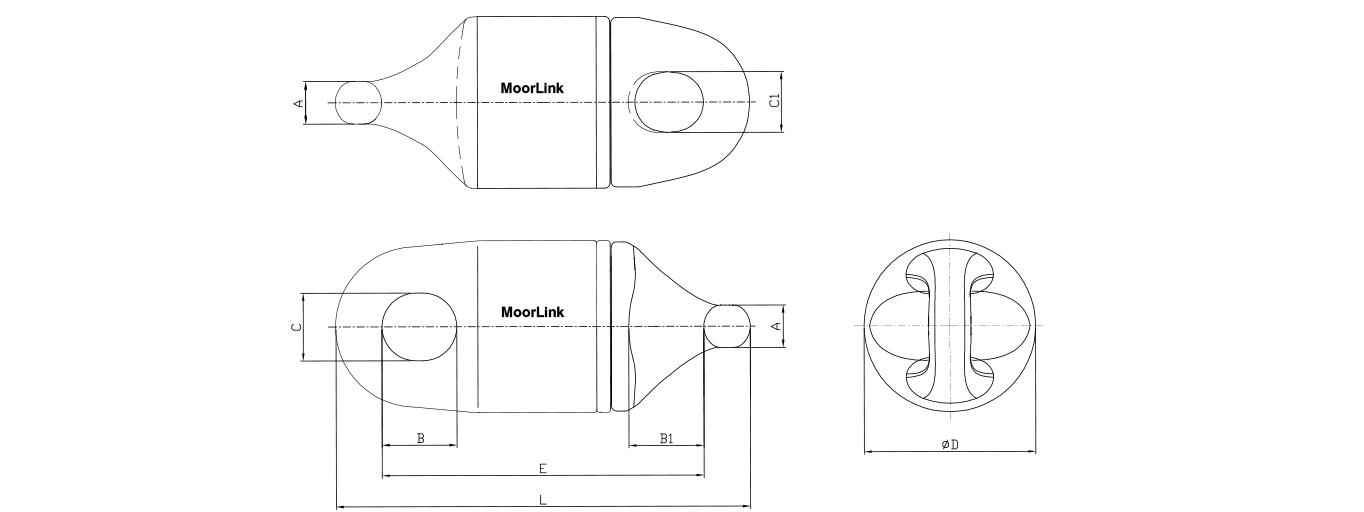

Mooring chain swivel M5-series

The M5-series has the same features as the regular chain swivels but are designed to also be used in R5 mooring lines. For example type 177 M5 can be used with 76mm R4, 76mm R5 and 84mm R4 mooring systems. The opportunity of using the same product for different applications is a big cost saving action and several clients have already discovered the advantages with MoorLink M5-series.

| Type | 251-M5 | 177-M5 | 231-M5 |

| MBL (kN) | 6021 | 7210 | 8420 |

| A (mm) | 77 | 84 | 92 |

| B (mm) | 127 | 148 | 150 |

| B1 (mm) | 127 | 136 | 150 |

| C (mm) | 121 | 133 | 140 |

| C1 (mm) | 121 | 120 | 140 |

| For R5 or R4 mooring systems |

| Certified by ABS, DNV GL or others |